A growing digital solutions firm managing internal hardware inventory across departments and remote teams. As their workforce crossed 200+ employees, they faced increasing difficulty tracking tech equipment using basic tools like Excel and Google Sheets. This limitation led them to design a scalable, internal warehouse management system that prioritized usability, synchronization, and administrative control.

Employees managed with real-time equipment tracking

Dependence on Excel or Google Sheets for inventory

Full development and deployment timeline

System integration with internal employee records

The Chalange

Managing technical inventory for a fast-growing company became increasingly inefficient using basic tools like Excel and Google Sheets. What once worked for 10 to 30 users quickly collapsed under the weight of 200+ employees and dozens of evolving requirements.

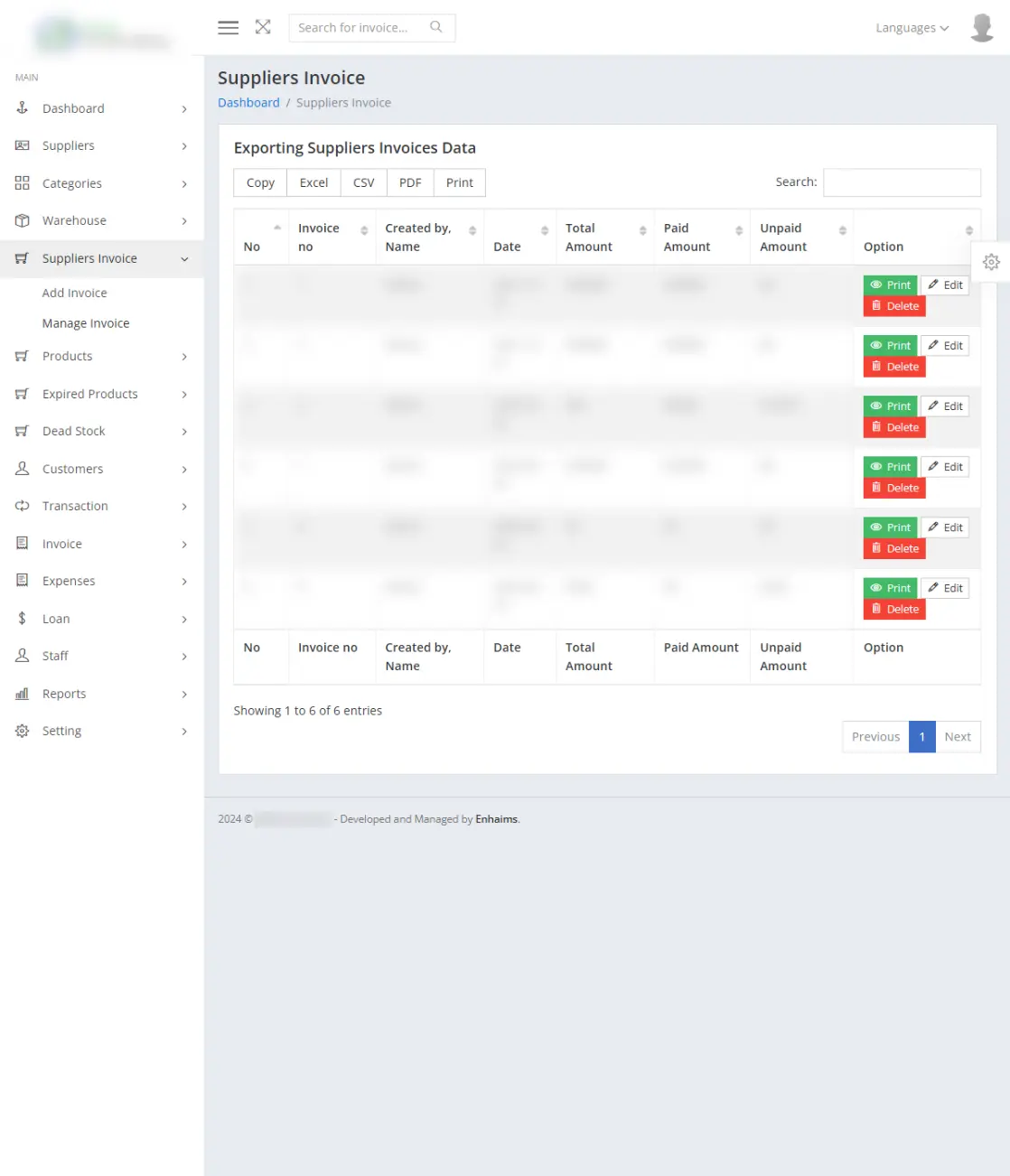

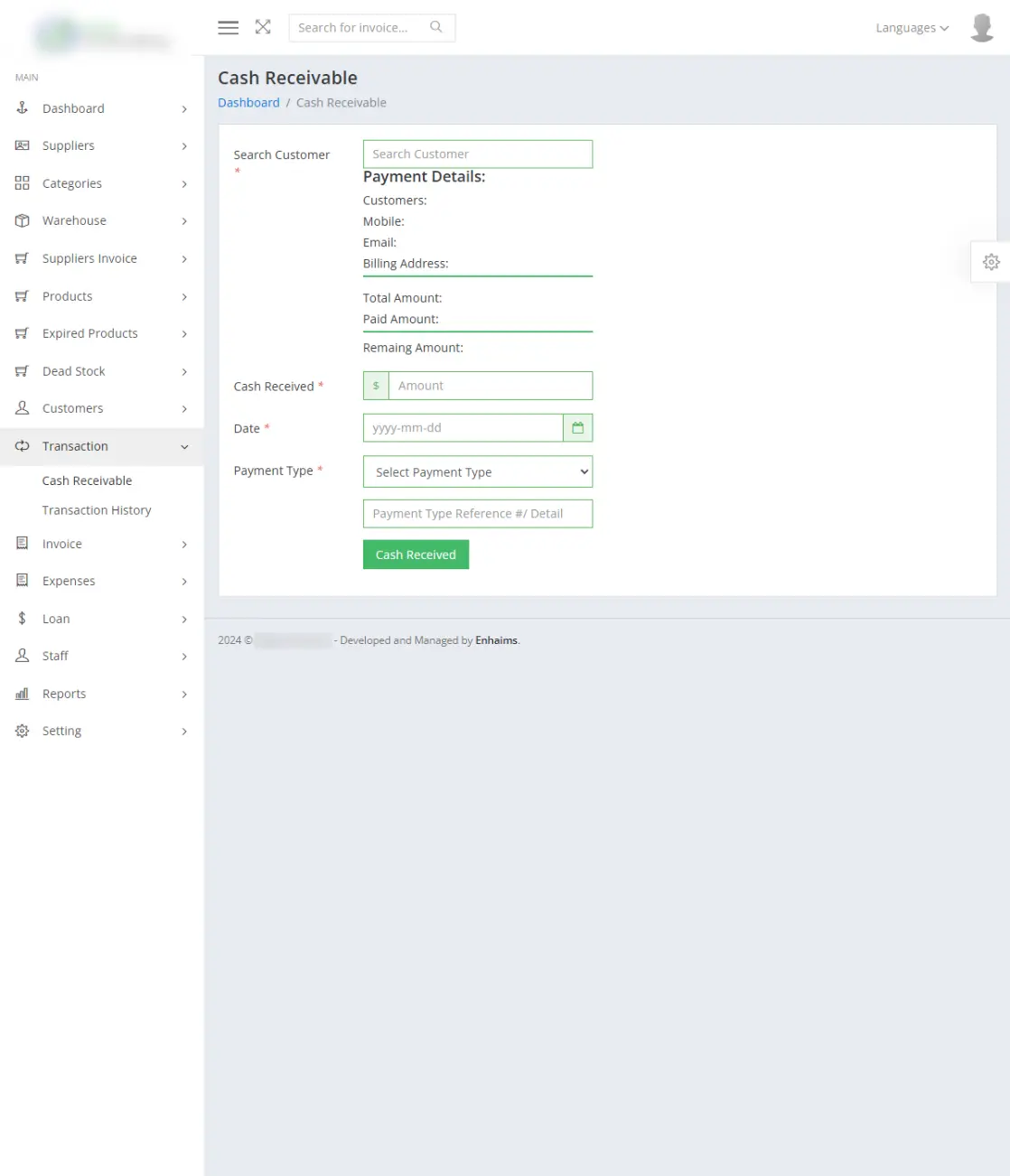

The organization needed a system that would allow their system administrators to view real-time availability of equipment, track assignments to specific employees or projects, and generate legally compliant reports with ease. The financial department also needed annual inventory data for shortages or overstock, while employees demanded a frictionless experience, minimal steps to access the tools they need.

Their internal reporting system already managed employee and project data, so the new warehouse management solution needed full synchronization, secure login protocols, and intuitive dashboards that required minimal training to operate.

What Did

Enhaims Do?

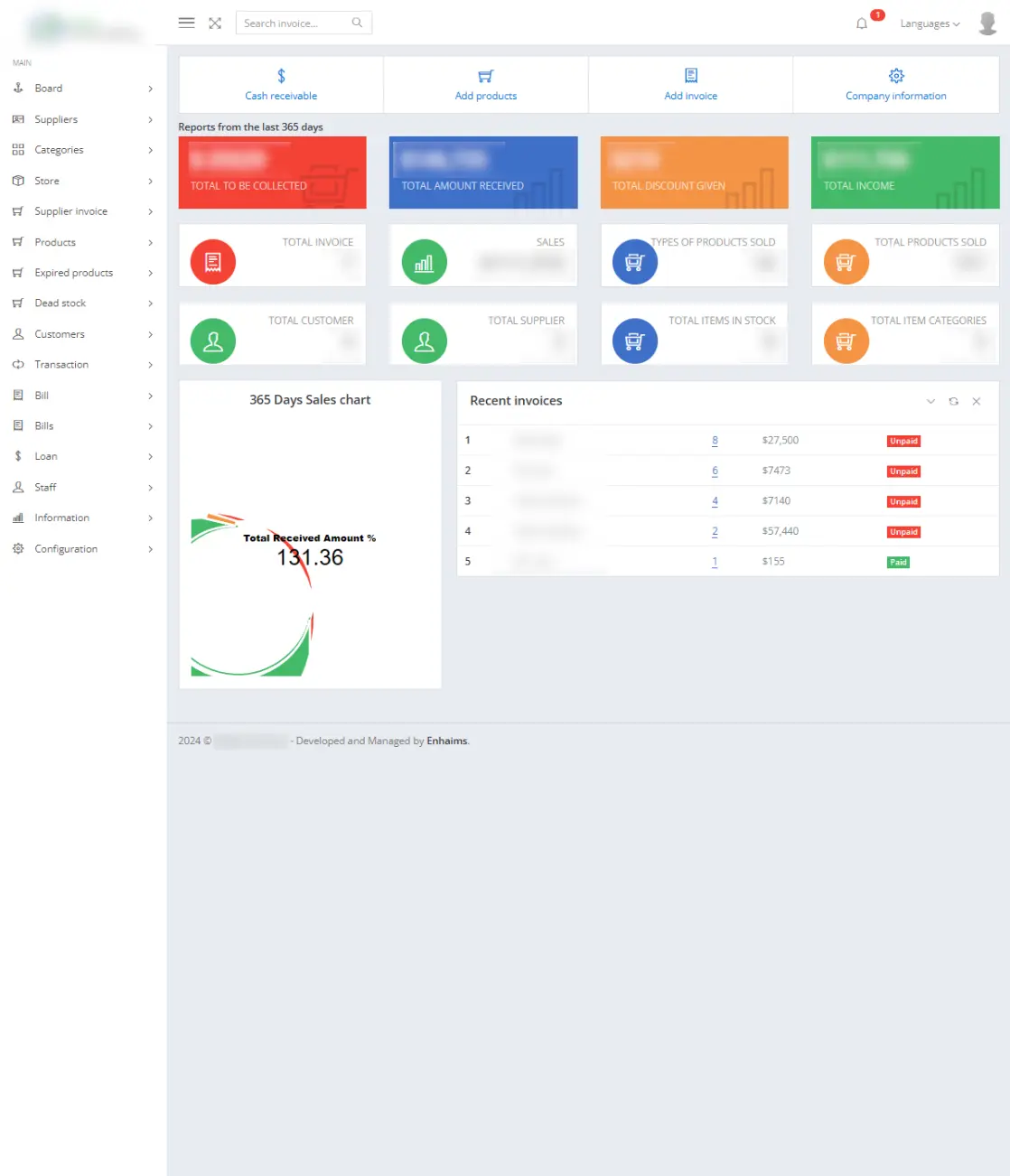

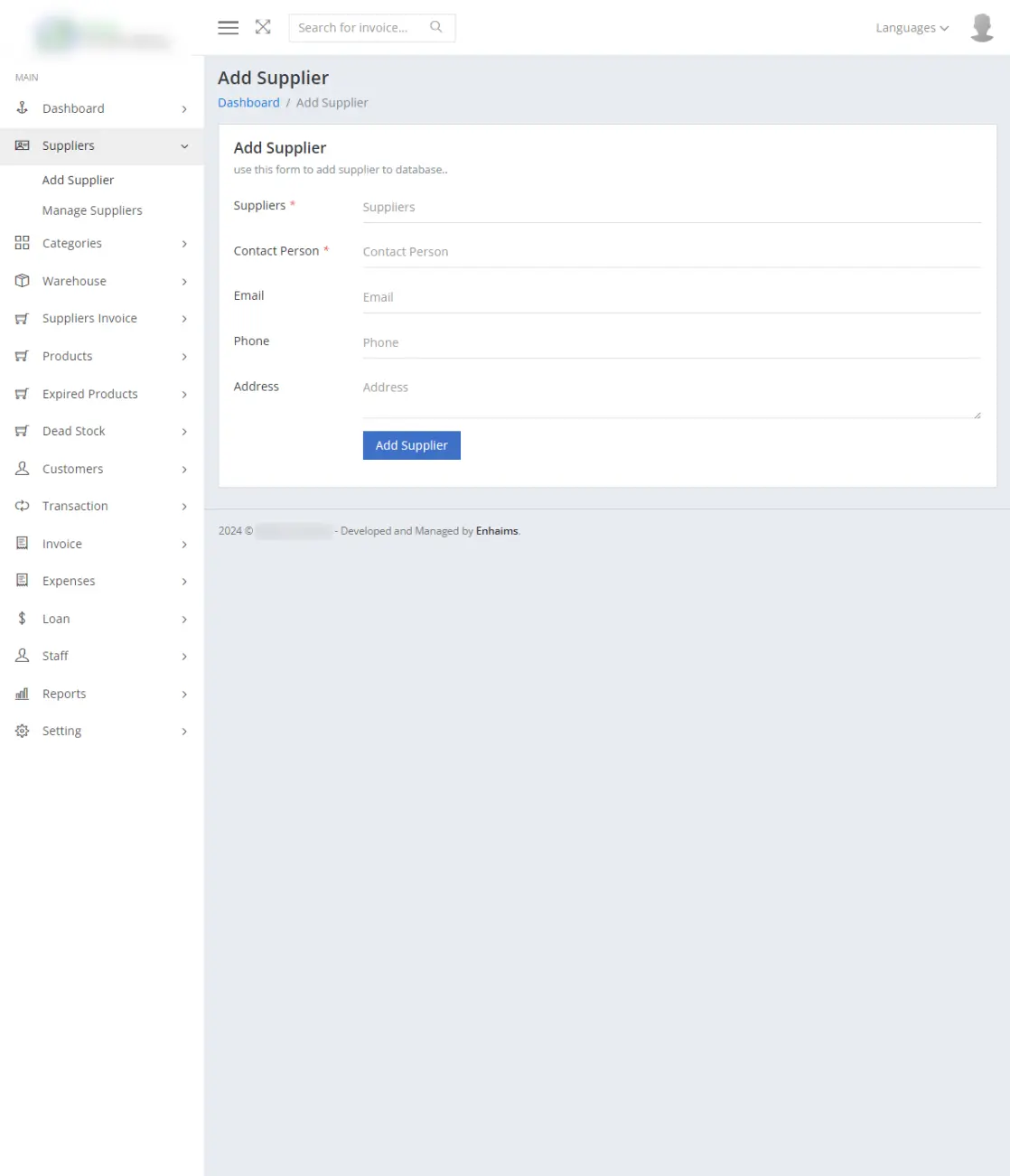

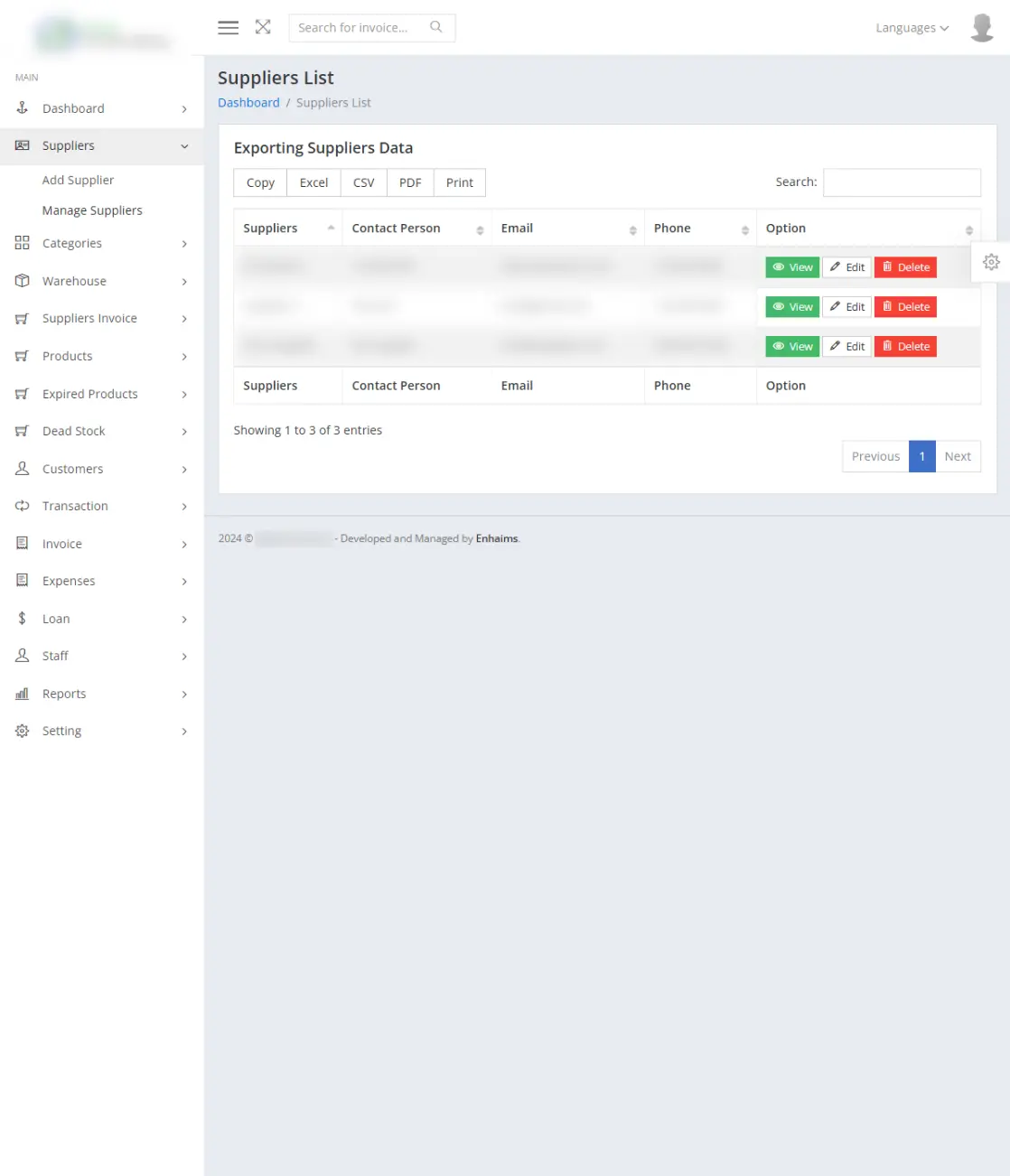

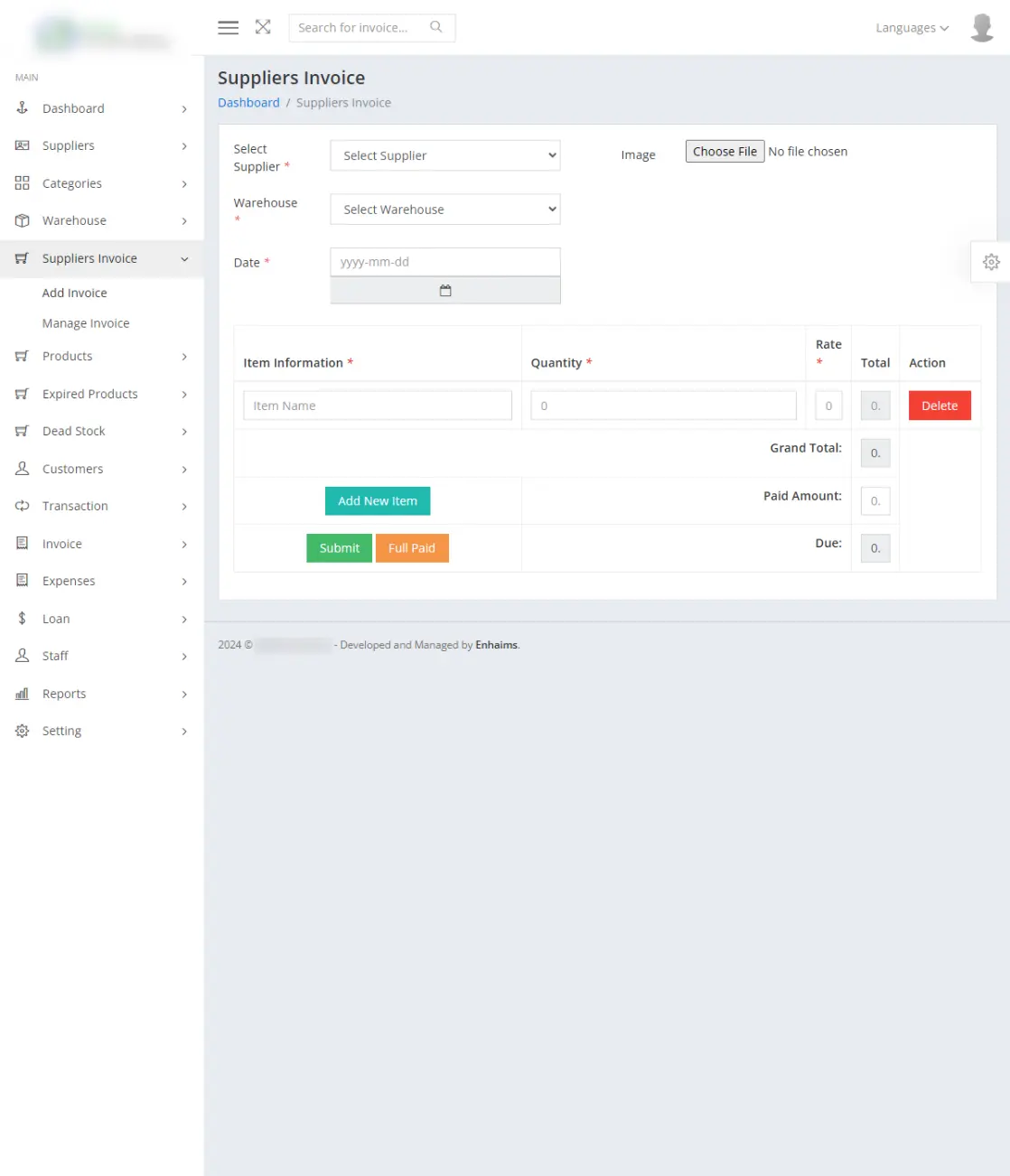

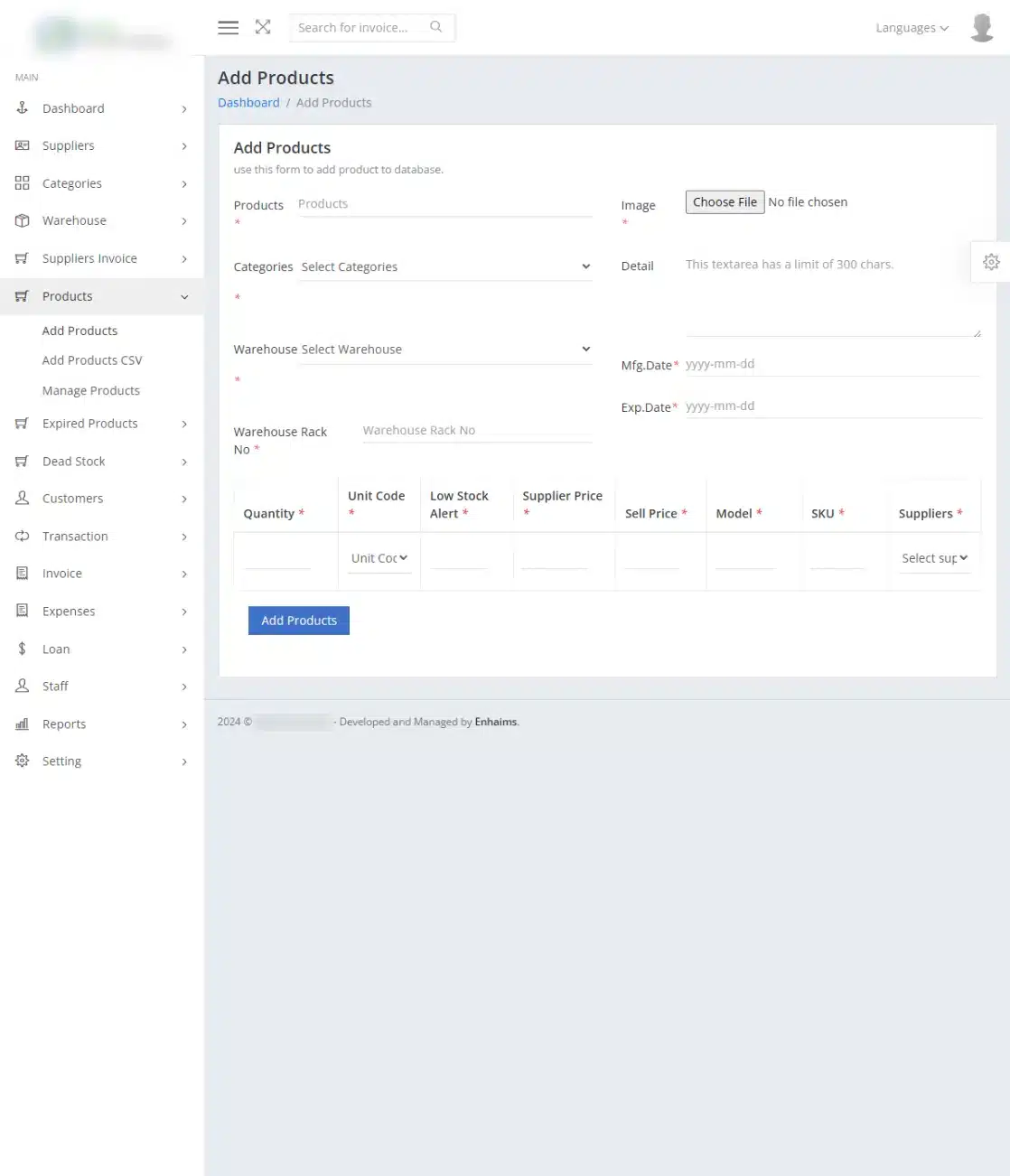

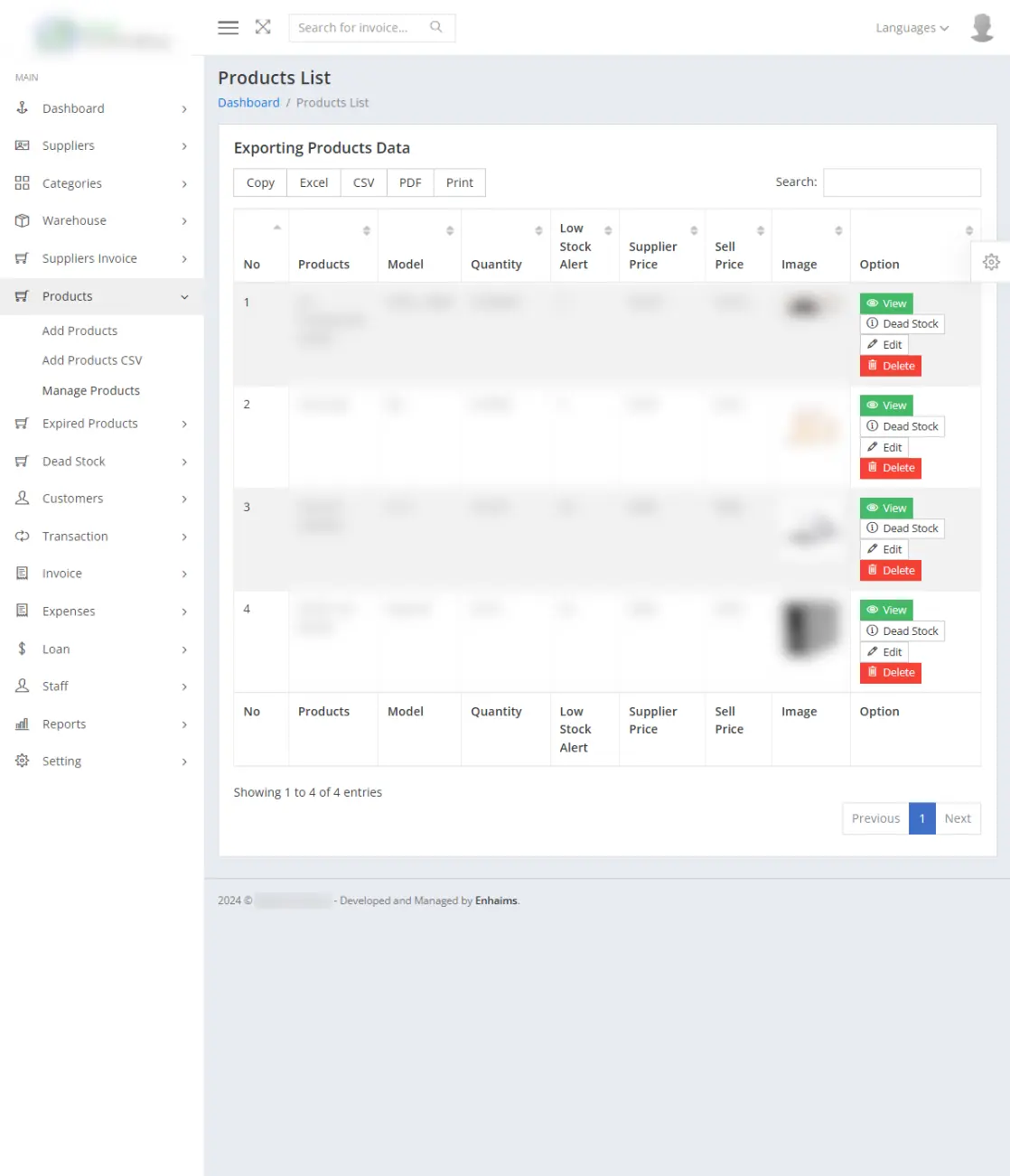

To support the growing inventory and operational complexity, Enhaims designed a fully custom Warehouse Management System tailored to the company’s workflow and infrastructure. Instead of relying on inflexible third-party tools, we created a lean and intuitive solution that eliminated spreadsheet dependency while keeping the user experience simple and efficient.

Our development team implemented a modern frontend interface backed by a powerful KoaJS backend and MySQL database. The system was integrated with the company’s internal reporting tools to ensure real-time synchronization of employee and project data. We also included granular equipment tracking, employee/project assignments, and role-based access control to maintain operational clarity and data integrity.

To make the system legally compliant and administrator-friendly, features such as Excel export, equipment history, repair tracking, and detailed dashboards were added. LDAP authentication was integrated to unify access across internal tools, reducing login friction while enhancing security across the organization.

The Results

- Full transition away from Excel and Sheets

- Real-time tracking of equipment assignments

- Instant export of legal-compliant inventory reports

- Reduced admin workload via LDAP-based login

- Custom widgets for fast data filtering and reporting

- Complete system built and deployed within 3 months